The Difference Between PCB and PCBA

PCB and PCBA are two common types in the electronic manufacturing field. Although they differ by only one letter, they have significant differences in structure and functionality. PCB is solely a base for circuits and does not possess independent circuit functions, whereas PCBA is a finished component with installed elements on the PCB, capable of performing specific circuit functions. This article will analyze their definitions, characteristics, and applications to help you better understand the manufacturing process of electronic products.

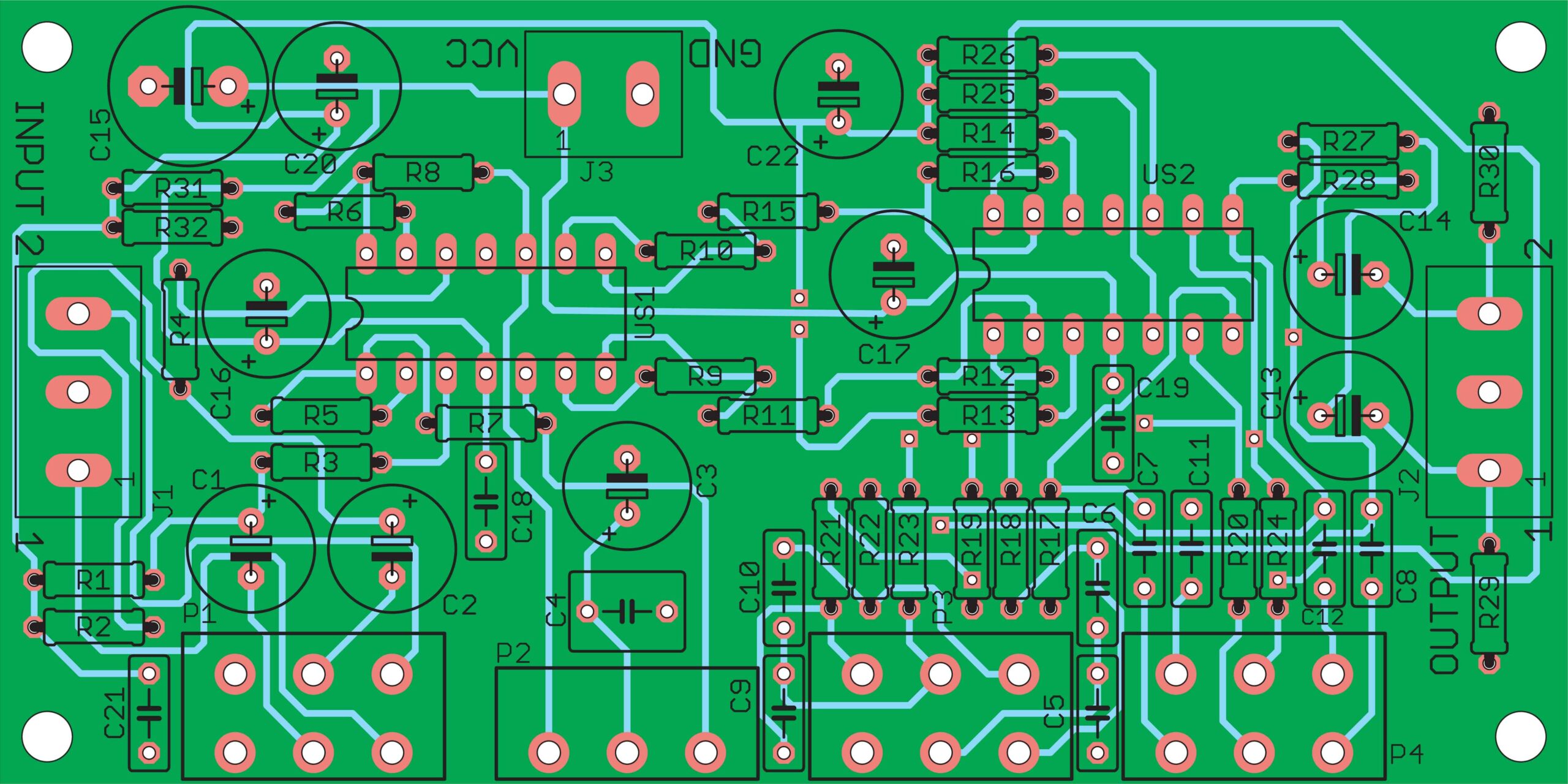

Definition of PCB

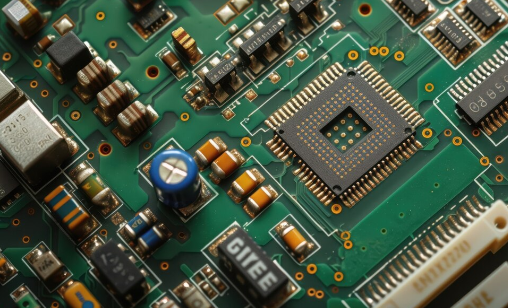

PCB, or Printed Circuit Board, is a passive circuit board that supports and connects electronic components. Designed with conductive traces and pads, PCBs can link various electronic components to form specific circuit functions. Structurally simple, PCBs primarily serve as support and electrical connectivity, making them indispensable foundational components in modern electronic devices.

Types of PCBs

Depending on the number of layers and materials, PCBs can be classified into several types, each with distinct features:

Single-layer PCB

Contains one conductive layer and is generally simple in structure, with low manufacturing costs. This is the most basic PCB type.

Double-layer PCB

Features two conductive layers, making it more suitable for multi-functional circuit design, with more routing options.

Multi-layer PCB

Comprising three or more conductive layers stacked internally, it offers greater flexibility in routing, ideal for high-density, complex circuits.

Rigid PCB

Made of rigid materials, it resists bending and deformation, providing stable support.

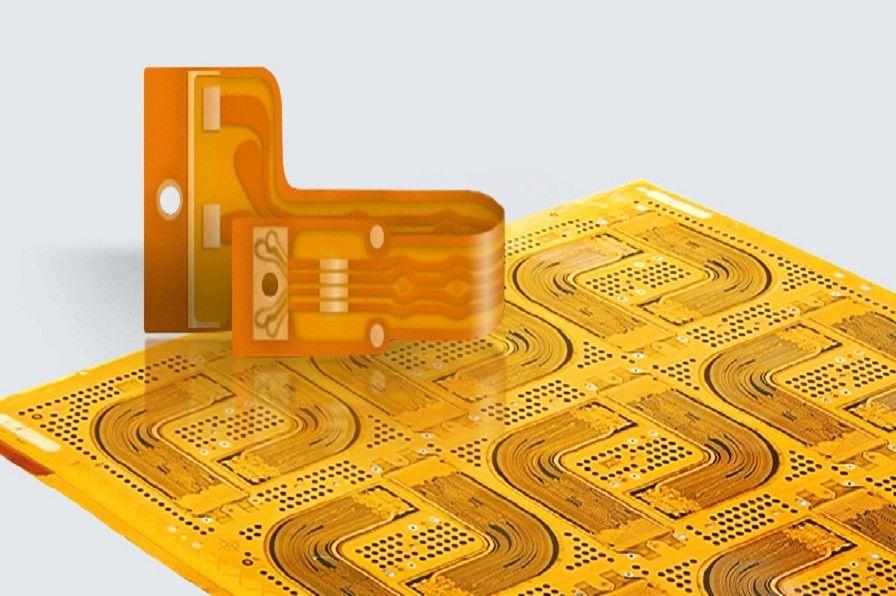

Flexible PCB: Made from flexible materials, allowing it to bend and fold, suitable for irregular shapes or devices requiring flexibility.

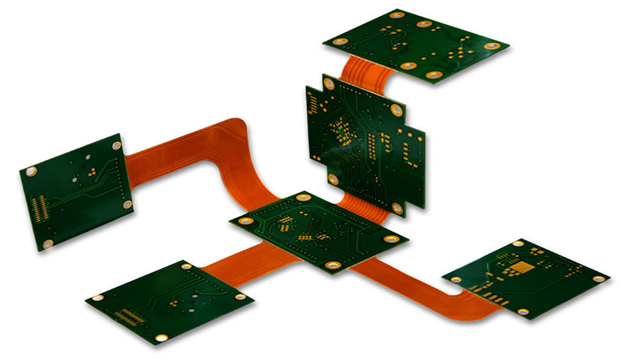

Rigid-Flex PCB

It combines the features of both rigid and flexible materials, which is advantageous in designs that require both rigid support and flexible regions.

PCB Materials

Material selection directly affects PCB performance and application scenarios. Common materials include:

FR-4

The main PCB material, made of fiberglass and epoxy resin, provides excellent electrical insulation and mechanical strength. Widely used in various circuit boards.

Metal-based materials

Often used in applications with high heat dissipation requirements, such as LED lighting and power electronics. Metal-based materials effectively reduce the working temperature of electronic components.

Flexible materials

Common in flexible PCBs, allowing bending and folding for complex structures and compact designs. Examples include polyimide (PI) and polyester (PET).

PCB Applications

PCBs are nearly universal in electronic products and devices. Based on different types and characteristics, PCB applications include:

- Consumer Electronics: Such as smartphones, tablets, televisions, and home audio devices.

- Industrial Automation: For industrial equipment, automated control systems, and robotics.

- Medical Equipment: Used in high-precision medical instruments like ECG machines, blood pressure monitors, and CT scanners.

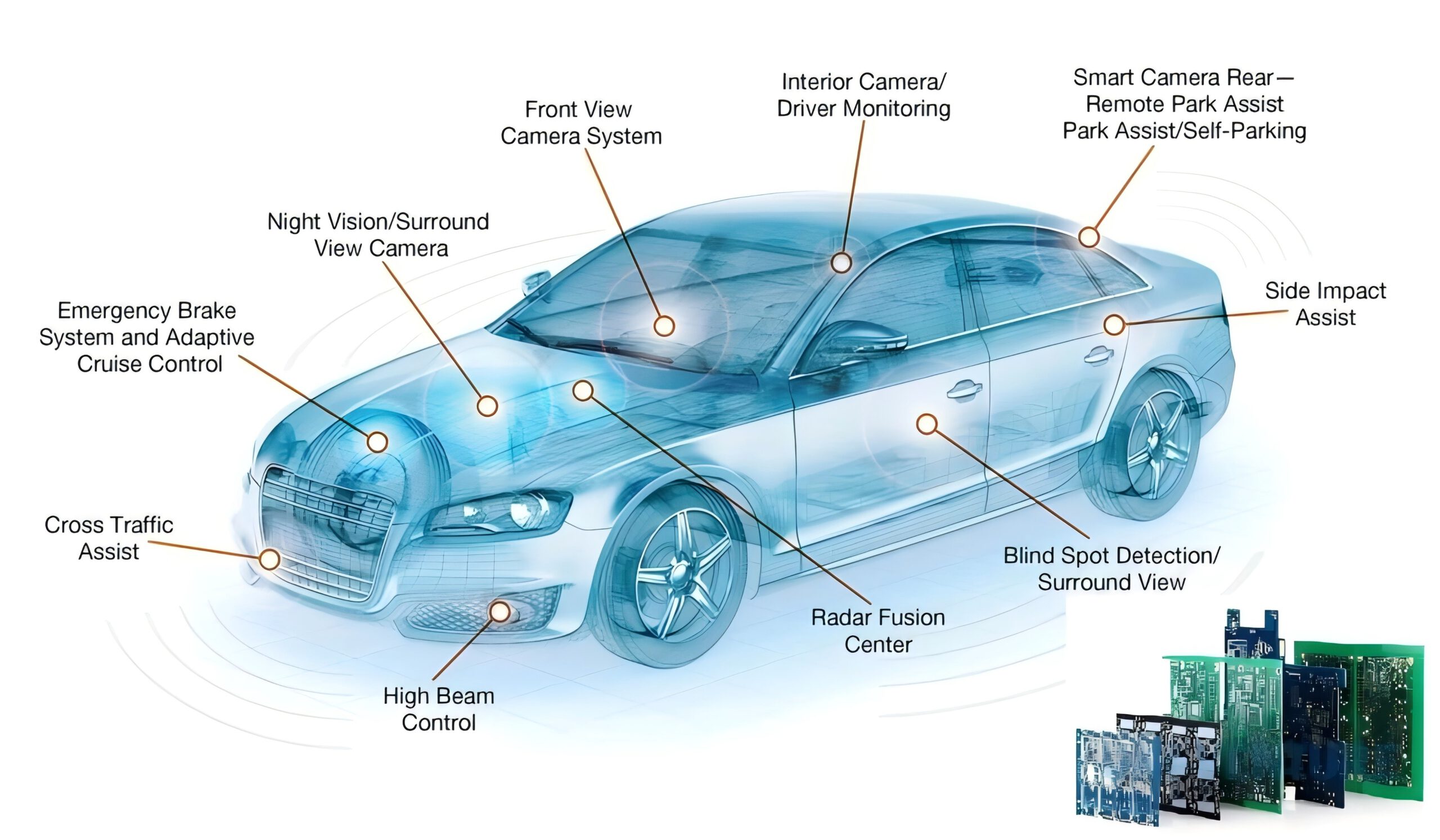

- Automotive Industry: Applied in-car infotainment systems, navigation systems, and engine control units.

- Aerospace: Involved in flight control, satellite communications, and radar systems.

PCBs play a crucial role in these fields, ensuring stable and efficient signal transmission between various components.

Definition of PCBA

PCBA, or Printed Circuit Board Assembly, refers to the process of installing electronic components on a PCB, creating a functional circuit assembly. PCBA can be seen as a finished circuit board, as the PCB now has full circuit functions and can be directly used for testing and assembly in electronic products. The PCBA manufacturing process typically includes steps like surface mounting, soldering, and testing to ensure normal circuit operation.

PCBA Assembly Techniques

PCBA assembly involves various techniques depending on component types and product requirements. Common techniques include:

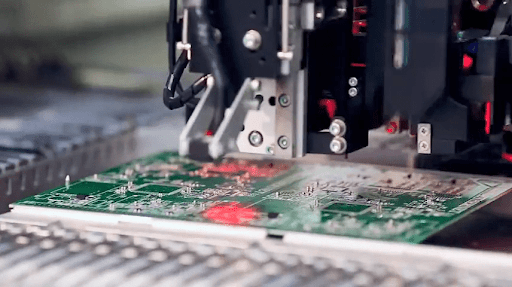

Surface Mount Technology (SMT)

Directly attaching components to the circuit board surface. SMT is high-density and compact, suitable for mass production with high efficiency and automation, becoming the mainstream process in modern electronics.

Through-Hole Technology (THT)

Pin-type components are inserted into PCB holes, and then soldering is done to secure them. THT is ideal for components requiring high mechanical strength, such as transformers and high-power capacitors.

Hybrid Technology

Combining SMT and THT on one circuit board is suitable for mixed component applications and a solution for complex circuits.

PCBA Costs

PCBA costs are influenced by several factors:

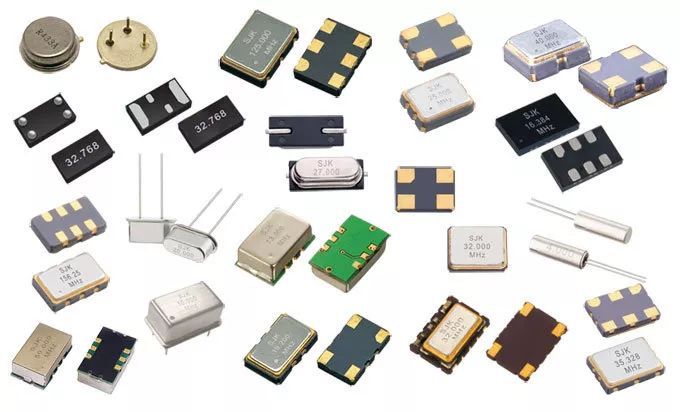

Component Costs

Different models and specifications vary in price. Rare or high-precision components are usually more expensive.

Production Process

SMT, THT, and other processes vary in complexity and require different equipment and process flows. Complex processes generally mean higher costs.

Assembly Complexity

Boards with numerous components and high routing density incur higher assembly and testing costs.

Cost control is crucial in PCBA manufacturing. Selecting appropriate components and processes and optimizing production flow can help reduce production costs while ensuring quality.

How to Choose a PCBA Manufacturer

Choosing a reliable PCBA manufacturer is essential for ensuring product quality and controlling costs. Key considerations include:

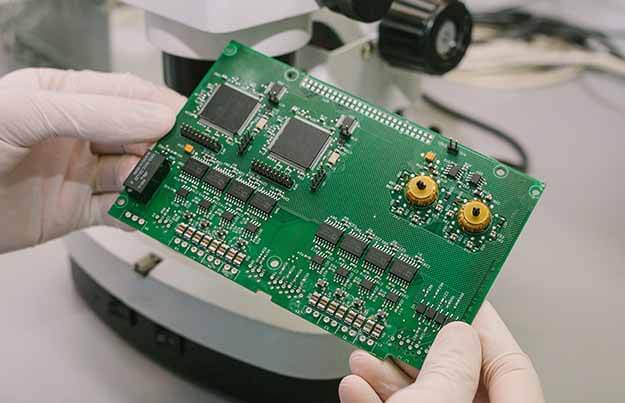

Quality Assurance

Preferably select manufacturers with certifications like ISO 9001 to ensure stable and reliable product quality.

Service Scope

A quality manufacturer should offer a wide range of services, including single-layer and multi-layer PCB design, rigid, flexible, and rigid-flex PCB manufacturing, as well as SMT, THT, and hybrid assembly methods to meet diverse customer needs.

Cost Control and Lead Time

A top manufacturer can meet customer quality requirements while controlling costs and delivery times. Evaluating their management in component sourcing, production processes, and logistics helps ensure cost advantages and timely delivery.

Conclusion

Though PCB and PCBA differ by only one letter, they play distinct roles in electronics. PCB is the base, carrying the circuit design and layout, while PCBA is the functional circuit assembly. For businesses, selecting a certified, comprehensive, and cost-effective PCBA manufacturer is essential. JY Electronic, an experienced manufacturer in the industry, can provide you with high-quality and reliable PCB and PCBA services. We welcome collaboration to create high-quality electronic products!

>>>Contact Us!