PCB EMS: A New Perspective on Electronic Manufacturing Services

With the rapid development of electronic products and the increasing complexity of market demands, Electronic Manufacturing Services (EMS) have become an essential solution for enterprises to optimize production processes and improve product quality. As a vital part of PCB EMS, these services cover the entire process from design and procurement to assembly and testing, making them indispensable in the electronics manufacturing industry.

Core Values of PCB EMS

One-Stop Service

PCB EMS provides end-to-end solutions, reducing the complexity of communicating with multiple suppliers and improving project management efficiency. With a unified service platform, enterprises can focus on product development and marketing while leaving production to professional teams.

Comprehensive Technical Support

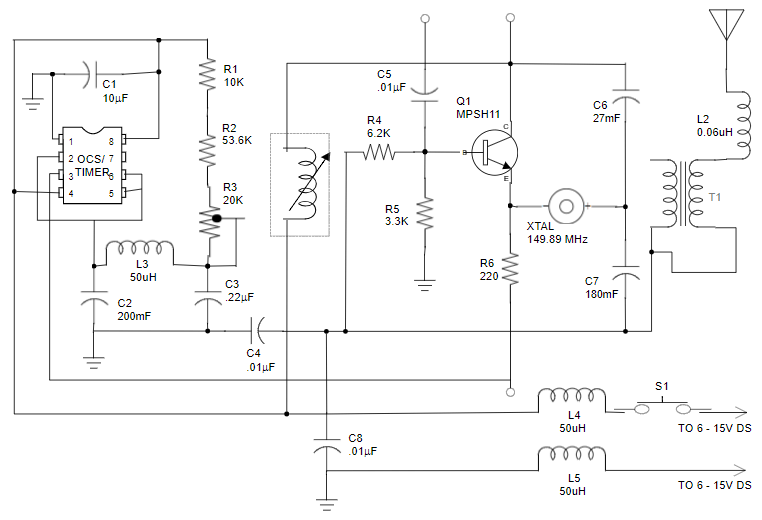

PCB EMS is more than just a manufacturing service; it extends technical support throughout the process. From design reviews to production process optimization, EMS providers help clients identify potential issues, offering Design for Manufacturability (DFM) and Design for Assembly (DFA) recommendations to ensure manufacturability from the start.

Efficient Supply Chain Management

The quality of components and the stability of the supply chain directly affect production schedules and product quality. PCB EMS providers often have a global procurement network, enabling them to respond quickly to market fluctuations, supply qualified components, and ensure timely delivery.

Key Aspects of PCB EMS Services

1. Product Design Optimization

EMS services go beyond production to include optimization suggestions for client designs. By evaluating designs with professional teams, potential production problems are avoided, saving costs for subsequent modifications and adjustments.

2. Customized PCB Manufacturing

Based on product requirements, suitable PCB materials, layers, and process parameters are selected. For instance, High-Density Interconnect (HDI) PCBs are ideal for consumer electronics, while rigid-flex boards are better suited for high-end communication devices. EMS providers deliver the best manufacturing solutions tailored to application scenarios.

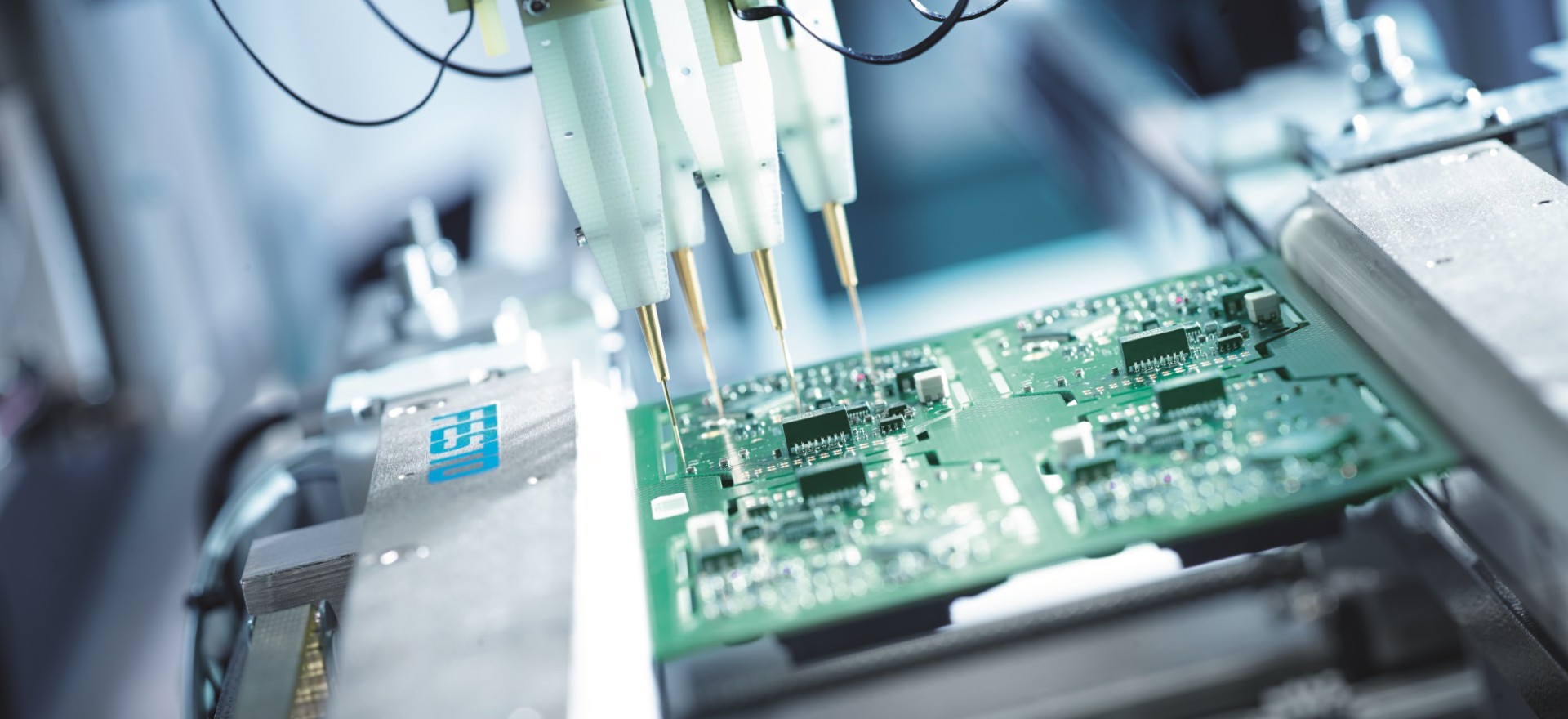

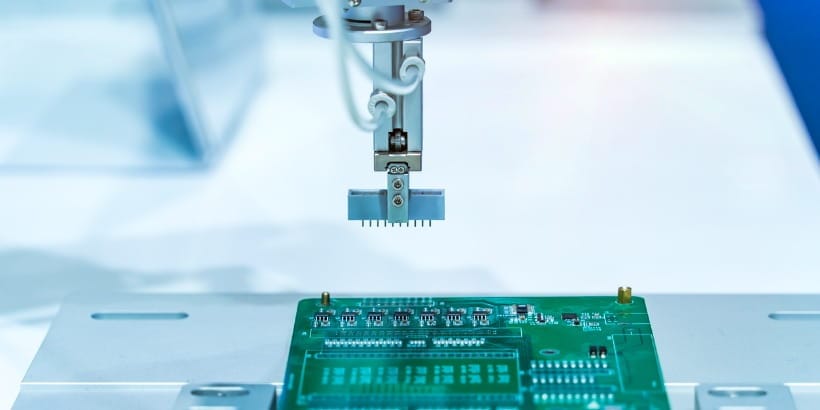

3. Precision Assembly and Testing

PCB assembly is a core aspect of EMS services, encompassing SMT placement, through-hole assembly, and functional testing. High-precision assembly and rigorous testing standards ensure the stability and reliability of product performance.

4. Quality Control and Packaging Services

Quality control runs through the entire production process, with finished products undergoing multiple inspections. EMS providers also offer customized packaging services to ensure product safety and enhance clients’ brand image.

Unique Advantages of PCB EMS

Flexibility to Meet Diverse Needs

Whether for small-scale prototyping by startups or large-scale production by established enterprises, PCB EMS offers flexible production models. For complex, customized requirements, EMS providers respond quickly with personalized solutions.

Cost Reduction

Outsourcing manufacturing eliminates the need for enterprises to invest in expensive production equipment and maintenance costs. Additionally, professional EMS providers reduce material costs through bulk procurement and streamline production processes, further saving expenses.

Enhanced Market Competitiveness

EMS services not only accelerate time-to-market but also enhance market competitiveness through high-quality manufacturing processes. Enterprises can leverage the expertise and experience of EMS providers to create more appealing products.

How to Evaluate PCB EMS Providers

Professional Certifications

Choose EMS providers with ISO 9001, UL certifications, and other qualifications to ensure compliance with international quality management standards. Such providers generally possess advanced technical capabilities and production levels.

Industry Experience and Client References

EMS providers with extensive industry experience better understand client needs and offer efficient, reliable solutions. Collaborations with well-known enterprises are strong indicators of their capability.

Customer Service and Technical Support

Excellent customer service is the foundation of long-term cooperation. Evaluate the responsiveness and professionalism of providers in after-sales support, technical communication, and problem-solving to ensure project success.

Conclusion

PCB EMS is more than a production service—it is the ideal partner for fast, precise, and flexible manufacturing. By choosing the right EMS provider, enterprises can focus on core business, enhance market competitiveness, and reduce production risks.

JY specializes in PCB and PCBA manufacturing, offering one-stop services from design optimization and component sourcing to testing and packaging. Our facilities are certified by multiple international standards and support the production of up to 24-layer PCBs, component sourcing, conformal coating, and packaging. With long-term collaborations with Fortune 500 companies such as BMW and Gree, we demonstrate our strength and credibility in the industry.

Contact us today to start a new era of efficient production!

Contact us: jy@pcbchina.cn

Visit our website: JY