What is PCB?

PCB (Printed Circuit Board) serves as the “neural network” of modern electronic devices, connecting various components into a complete system and bringing devices to life. From smartphones to industrial equipment, PCBs are ubiquitous. But do you truly understand its structure, types, and how it works? In this article, we will delve into the anatomy, types, applications, and critical roles of PCBs in electronic products, unveiling the mysteries behind this essential technology.

What is a PCB?

PCB, or Printed Circuit Board, is a board created by etching conductive pathways and pads onto an insulating substrate, serving the dual purpose of providing electrical connections and mechanical support.

In the realm of electronics manufacturing, PCB and PCBA (Printed Circuit Board Assembly) are often confused. PCB refers to the bare board without any components, forming the foundation of a device, while PCBA is the assembled version with components mounted to perform specific functions. In other words, PCB is the “skeleton,” while PCBA is the “soul.” Together, they form the heart of an electronic device.

Components of a PCB

Despite appearing simple, every part of a PCB serves specific functions and meets technical requirements. These components collectively determine the performance and reliability of the PCB.

1. Substrate Material

The substrate is the core supporting material of a PCB. Common materials include FR-4 (fiberglass laminate), CEM1/3, and PTFE. FR-4 is widely used for its excellent electrical properties and mechanical strength, while PTFE (polytetrafluoroethylene), known for its superior high-frequency performance, is used in communication applications requiring high-frequency circuit boards.

2. Conductive Layer

The conductive layer, typically made of copper foil, is responsible for transmitting electrical signals. The thickness of the copper foil and the design of the circuitry directly impact the PCB’s conductivity and heat dissipation. In high-frequency or high-power applications, the design of the conductive layer requires a balanced consideration of signal integrity and electrical loss.

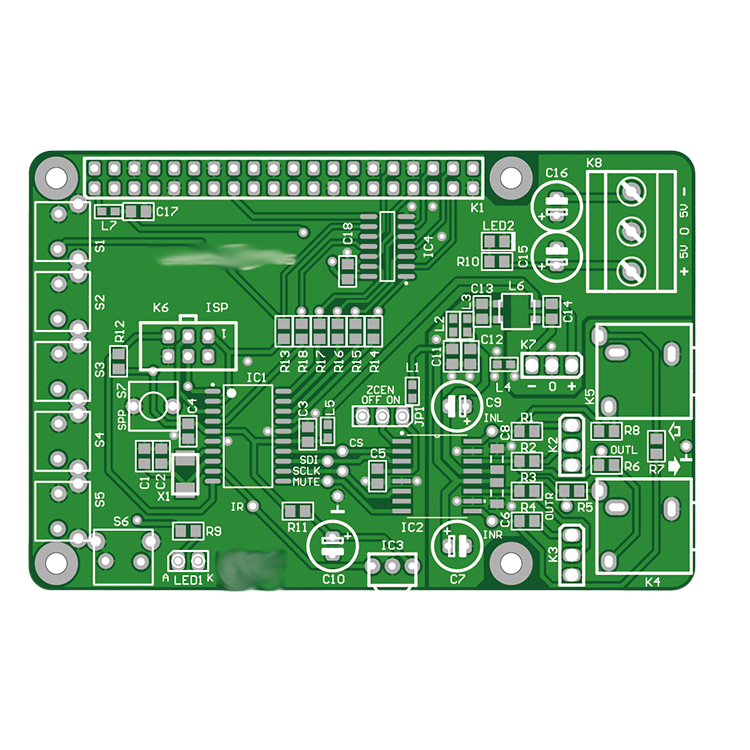

3. Pads and Plated Through-Holes

Pads connect electronic components, while plated through holes provide electrical pathways between layers. High-quality pad design ensures secure soldering, while uniformity and conductivity in the through-hole plating are essential for the stability of multilayer PCBs.

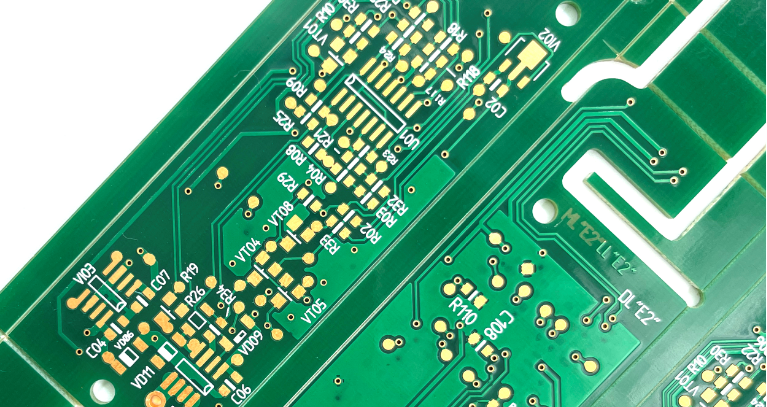

4. Solder Mask and Silkscreen

The solder mask covers the copper surface, preventing short circuits or oxidation and enhancing insulation. The silkscreen identifies component locations and circuit information, facilitating assembly and maintenance.

Types of PCBs

Depending on design needs and application scenarios, PCBs can be categorized into several main types:

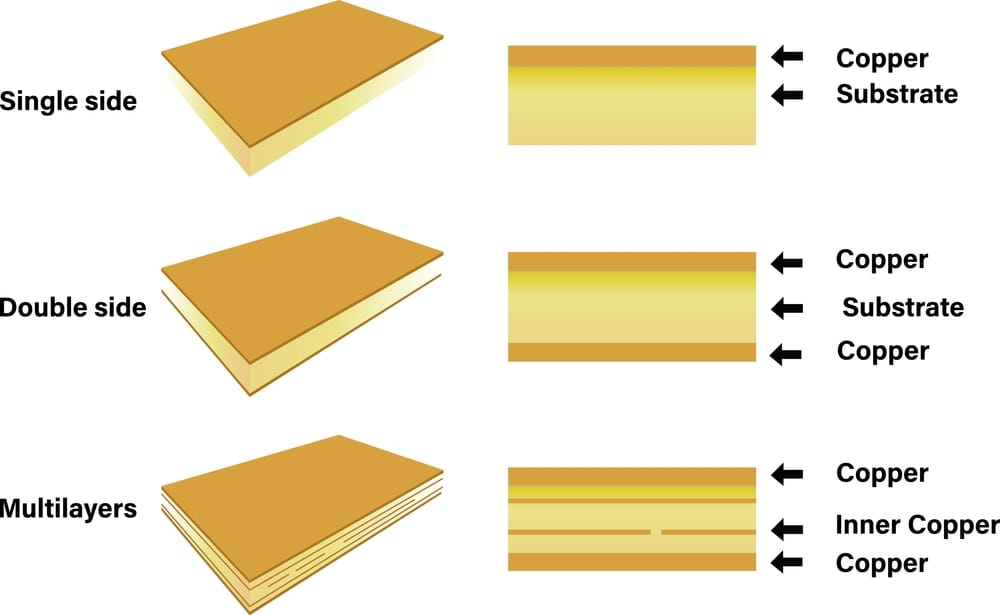

1. By Layer Count

Single-Sided PCB: Features a single conductive layer; suitable for simple circuits.

Double-Sided PCB: Has conductive layers on both sides, interconnected through vias, suitable for moderately complex designs.

Multilayer PCB: Includes multiple conductive layers, with internal and external connections enabling complex circuits; widely used in computers and communication equipment.

2. By Flexibility

Rigid PCB: High mechanical strength; ideal for most fixed devices.

Flexible PCB: Can bend and fold, making it suitable for space-constrained or dynamic devices like wearable electronics.

Rigid-Flex PCB: Combines the stability of rigid PCBs with the flexibility of flexible ones, ideal for high-end electronics.

3. By Function

High-Frequency PCB: Used for high-frequency signal transmission in communication devices; demands stringent material and process requirements.

HDI PCB: High-Density Interconnect technology allows for smaller, more functional PCBs, widely used in smartphones and tablets.

How PCBs Work

The primary role of a PCB is to create precise conductive pathways and electrical connections to enable the functionality of electronic devices. This involves multiple stages, including design, manufacturing, and testing.

1. Design and Layout

PCB design includes schematic drawing, network routing, and thermal management. Efficient routing avoids signal interference, while effective thermal management ensures stable operation under high loads.

2. Manufacturing Process

Starting with design schematics, PCB manufacturing involves processes such as copper cladding, etching, drilling, plating, and silkscreen printing, culminating in panelization and inspection. Each step demands high precision to ensure the final product meets design specifications.

3. Functionality Implementation

By connecting components through conductive paths, PCBs enable the transmission, processing, and conversion of electrical signals. Finished PCBs typically undergo rigorous electrical testing to ensure reliability in application.

Applications of PCBs

Thanks to their efficiency and versatility, PCBs find applications in a wide range of fields, forming the backbone of modern technology across industries.

1. Communication and Computing

In communication, PCBs are the core of devices such as routers, base station antennas, and optical communication equipment, ensuring high-speed data transmission and stable signal processing. For computers, PCBs constitute the backbone of motherboards, graphics cards, and storage devices, supporting complex operations and information processing. High-frequency and HDI PCBs are particularly critical in these applications, maintaining signal integrity and high performance.

2. Industrial and Household Devices

In industrial equipment, PCBs enable complex automation control systems, power distribution units, and sensor connections, ensuring efficient operation. For example, industrial robots rely on PCBs to support their controllers, achieving precise movements and feedback. In household appliances, PCBs are widely used in washing machines, refrigerators, and air conditioners, ensuring stable functionality, user convenience, and efficient energy management.

3. Medical Electronics

In the medical field, PCBs are integral to sophisticated diagnostic and therapeutic devices, such as CT scanners, ECG monitors, and portable ultrasound machines. High-density PCB designs meet the stringent accuracy and reliability requirements of medical equipment, particularly in minimally invasive surgical tools and monitoring devices.

4. Automotive and Transportation

With the rise of automotive electronics, PCBs play crucial roles in powertrain control systems, navigation systems, entertainment devices, and autonomous driving modules. Flexible PCBs are widely used in vehicles, accommodating wiring needs in confined spaces while enhancing stability and shock resistance.

Advantages of PCBs

The advent of PCBs has revolutionized the design and production of electronic devices. Their remarkable technical advantages have made them the cornerstone of modern electronic manufacturing, driving continuous technological and industrial development.

1. Enhanced Performance and Reliability

Compared to traditional manual wiring methods, PCBs offer more stable electrical performance and higher reliability. Precisely designed conductive paths and high-quality soldering significantly reduce signal interference and loss. In high-frequency and high-speed devices, PCBs ensure signal integrity and device stability.

2. Space and Cost Efficiency

Optimized design enables PCBs to achieve complex electrical functions within limited space, paving the way for miniaturized products. For example, multilayer PCBs in smartphones and wearable devices integrate numerous functional modules, significantly reducing product size and weight. Additionally, standardized manufacturing processes and automated production techniques further lower PCB costs, catering to large-scale production needs.

3. Support for Modular Design and Maintenance

Modular PCB design simplifies fault detection and maintenance. Whether replacing individual modules or upgrading entire systems, tasks can be completed quickly, improving maintenance efficiency. Modular design also facilitates functional expansion, particularly in industrial automation and communication devices.

4. Adaptability to Diverse Needs

The versatility of PCBs allows them to meet varied application requirements. For instance, high-frequency PCBs suit high-speed data transmission, rigid-flex PCBs cater to flexible wiring needs, and metal-core PCBs excel in high-temperature, high-power scenarios. This flexibility offers manufacturers more choices and accelerates the development and adoption of new technologies.

Conclusion

As the foundation of modern electronic devices, PCBs ensure the functionality and performance of electronic products. From meeting high-speed demands in communication to withstanding harsh conditions in industrial equipment, PCBs play an indispensable role.

At JiaYuan, we have accumulated extensive experience in PCB manufacturing and provide one-stop services from design to mass production. Our team specializes in tackling complex project requirements, offering high-quality custom solutions, whether for high-frequency PCBs, rigid-flex boards, or multilayer boards.

If you have PCB requirements, please feel free to contact us. Let JiaYuan be your strong partner in electronic manufacturing!